3D Studio : Stained Glass

- Nitika Jain

- Jan 3, 2021

- 4 min read

Updated: Mar 27, 2021

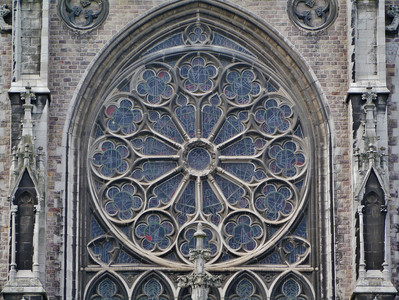

Stained Glass

A colorful Expression

By Nitika Jain

I often find peacefulness and tranquility in Mehrangarh Fort at Jodhpur, a cool place to sit and contemplate. The giant trunk-like pillars and the gentle play of the light cast through the stained glass create a shaded garden of stone and multicolored light

Stained glass windows are never static. In the course of the day, they are animated by changing lights, their patterns wandering across the floor, tempting & inviting your thoughts to wander with them.

Elements And Principles Of Design

Stained glass is probably the most intractable & ungovernable of all other media since it exploits the interaction between two highly dynamic phenomena, the one physical and the other organic. The physical factor is the light- the intensity of particular light sources that occurs not only from moment to moment but from place to place—a forest, a greenhouse to any other place as a matter of fact. The other phenomenon is the spontaneous light-adaptive process of vision, which seeks to maintain orientation in all luminous surrounding

Evolution of The Technique

Stained glass windows have been around for a long time, During medieval times, stained glass windows were made from a combination of sand and potash (wood ash). These two ingredients were heated to the point where they’d liquefy and become glass when cooled. In order to color the glass, powdered metals were added into the molten (heated) mixture before it cooled.

Stained glass was a mosaic of different shapes and sizes of glass, first assembled on a drawn piece of board to map out their placements. If there was a need for shadows or outlines, artists would use black paint to add these details to the glass.

In order to connect the pieces of stained glass in their patterns as determined by the artist, lead was used along with putty. When put together like pieces of a puzzle, the whole window became stabilized by an iron frame. That’s how stained glass windows were made during The Middle Ages.

Making of Stained Glass

Raw Materials:

Glass is made by fusing together some form of silica such as sand, an alkali such as potash or soda, and lime or lead oxide. The color is produced by adding a metallic oxide to the raw materials.

Copper oxide, under different conditions, produces ruby, blue, or green colors in glass. Cobalt is usually used to produce most shades of blues. Green shades can also be obtained from the addition of chromium and iron oxide.

Process Of Making:

Large manufacturers of stained glass mix the batch of raw materials, including alkaline fluxes and stabilizing agents, in huge mixers. The mix is then melted in a modern furnace at 2500°F (1371°C). Each ingredient must be carefully measured and weighed according to a calculated formula, in order to produce the appropriate color. For cathedral glass, the molten glass is ladled into a machine that rolls the glass into 1/8-inch (3.2 mm) thick sheets. The sheets are then cooled in a special furnace called an annealing lehr. The glass is then inspected, trimmed to a standard size, and packed into cases.

Creating the window pattern

The first step of the process involves the artist creating a small-scale version of the final design. After the design has been approved, the craftsperson takes measurements or templates of the actual window openings to create a pattern. This pattern is usually drawn on paper or cardboard and is the space's actual size to be filled with glass. Next, a full-sized drawing called the cartoon is prepared in black and white. From the cartoon, the cutline and pattern drawings are made.

Cutting and painting

Colored glass is then selected from the supply on hand. The pattern is placed on a piece of the desired color, and with a diamond or steel wheel, the glass is cut to the shape of the pattern. After the glass has been cut, the main outlines of the cartoon are painted on each piece of glass with special paint, called "vitrifiable" paint. This becomes glassy when heated. The painter might apply further paint to the glass in order to control the light and bring all the colors into closer harmony. During this painting process, the glass is held up to the light to simulate the same conditions in which the window will be seen. The painted pieces are fired in the kiln at least once to fuse the paint and glass.

Glazing and leading

The next step is glazing. The cutline drawing is spread out on a table and narrow strips of wood called laths are nailed down along two edges of the drawing to form a right angle. Long strips of grooved lead are placed along the inside of the laths. The piece of glass belonging to the angle is fitted into the grooves. A strip of narrow lead is fitted around the exposed edge or edges and the next required segment slipped into the groove on the other side of the narrow lead. This is continued until each piece has been inserted into the leads in its proper place according to the outline drawing beneath.

Finishing

The many joints formed by the leading are then soldered on both sides and the entire window is waterproofed. After the completed window has been thoroughly inspected in the light, the sections are packed and shipped to their destination where they are installed and secured with reinforcing bars.

In a nutshell, I immensely feel that Stained glass is a Heavenly illumination exhibiting the sheer magic of science, where the glass itself is one of the fruits of the art of fire. Every time I walked closer to them, their aesthetic beauty portrayed vivid simplicity. As you get closer, you will notice the amazing use of lead and colored glass to form these illustrations. Closer still and the individual & distinct colors, staining, and shading start coming into the center of attention ...

Comments